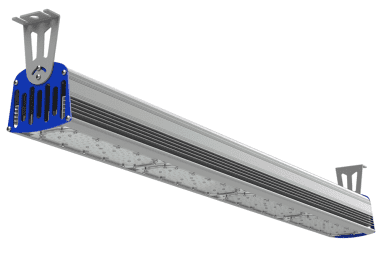

In modern industrial environments, good lighting is crucial for enhancing work efficiency and ensuring safety. LED linear industrial lights are increasingly used in factories and warehouses due to their high efficiency and long lifespan. Selecting the appropriate LED linear industrial light involves considering various factors, including the performance of the fixtures, applicable scenarios, and maintenance requirements.

Advantages of LED Linear Industrial Lights

1.High Energy Efficiency

LED fixtures are more efficient than traditional lighting (such as fluorescent and incandescent lights), consuming less power for the same light output. This helps reduce energy costs and has a positive impact on environmental protection.

2.Long Lifespan

LED fixtures typically last over 50,000 hours, compared to 10,000 hours for traditional lights. This reduces the frequency of replacements and maintenance costs, making them suitable for long-term use in factories and warehouses.

3.Good Light Quality

LED fixtures provide uniform lighting, minimizing shadows and glare, which enhances the comfort of the working environment and improves worker efficiency.

4.Strong Durability

LED fixtures are usually made from robust materials, making them resistant to impact and vibration, suitable for harsh working conditions in factories and warehouses.

5.Eco-Friendly

LED fixtures do not contain harmful substances like mercury and comply with environmental standards, making them recyclable and helping reduce waste’s environmental impact.

Selecting Suitable LED Linear Industrial Lights

When choosing LED linear industrial lights, consider the following aspects:

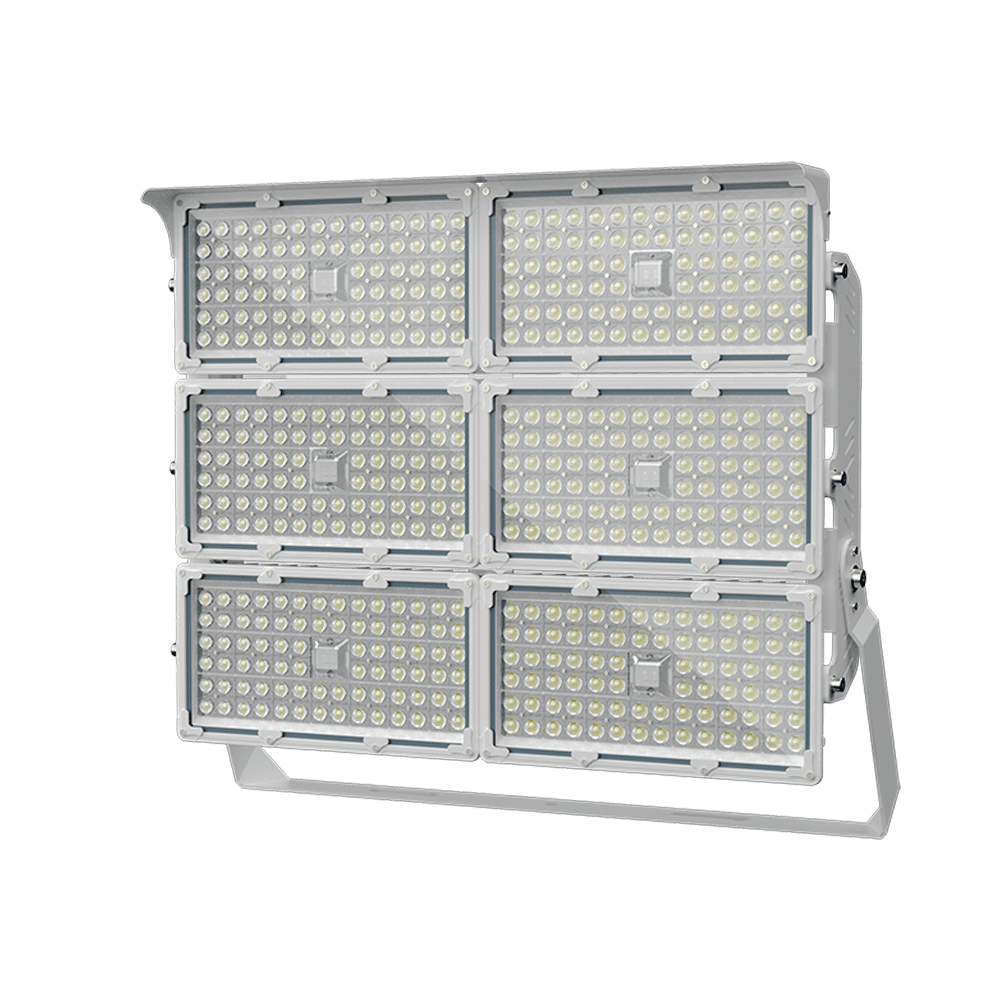

1.Luminous Flux and Brightness

Select the appropriate luminous flux based on specific needs. Generally, workplaces require higher lighting levels, typically around 300-500 lumens per square meter, while warehouses may have slightly lower standards.

2.Color Temperature

LED fixtures are available in color temperatures ranging from 3000K to 6000K. For precision work areas, cooler white light (4000K-6000K) is recommended, while warmer white light (3000K-4000K) may be preferable for warehouses to enhance comfort.

3.Protection Rating

Choose an appropriate protection rating (such as IP65 or higher) to ensure the fixtures can withstand dust and moisture, extending their lifespan, especially in humid or dusty environments.

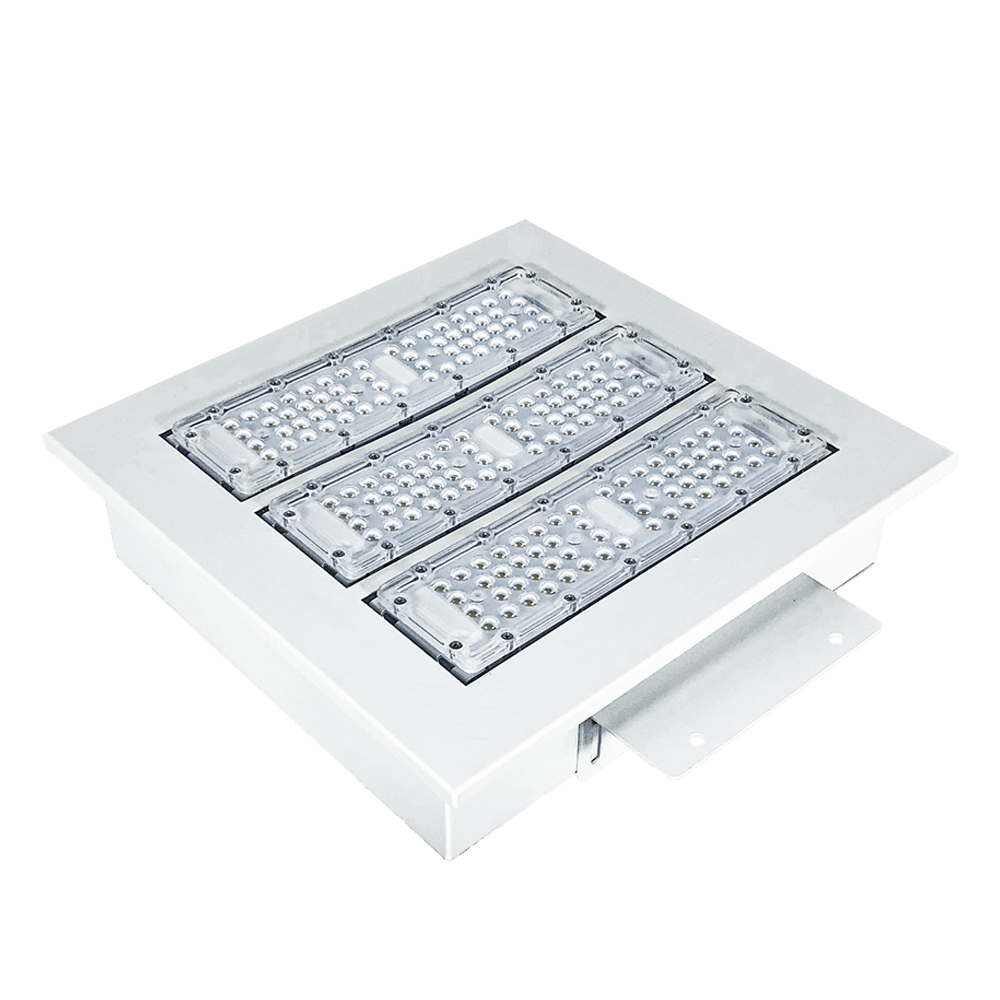

4.Installation Method

Depending on the structure and layout of the actual site, select a suitable installation method. LED linear industrial lights can be suspended, wall-mounted, or track-mounted, providing flexibility for various environments.

Maintaining LED Linear Industrial Lights

1.Regular Inspections

Conduct regular inspections of LED fixtures to ensure there are no damages or signs of aging, particularly at the connections and power lines. Replace any damaged components promptly.

2.Clean the Fixtures

Dust accumulation on the fixture surfaces can affect light output. Regularly clean fixtures with a damp cloth to ensure optimal lighting performance.

3.Monitor Power Supply

Ensure the stability of the power supply to avoid voltage fluctuations that could damage the lights. Consider using a voltage stabilizer if necessary.

4.Record Usage

Keep a record of the usage and maintenance of the fixtures to identify and address potential issues promptly.

In summary, selecting the right LED linear industrial light can significantly improve the lighting quality in factories and warehouses while saving energy costs for businesses. Paying attention to the above points during purchasing and maintenance will help achieve the best lighting effects and economic benefits.