In modern industry and mining, good lighting conditions are essential for ensuring safety and improving work efficiency. Led high bay lights, designed specifically for these environments, feature high brightness, durability, and explosion-proof characteristics, making them widely used in mines, warehouses, factories, and other settings. This article will explore the application scenarios of Led high bay lights and provide guidance on how to select and install the appropriate fixtures.

Main Applications of Industrial and Mining Lights

1.Mining

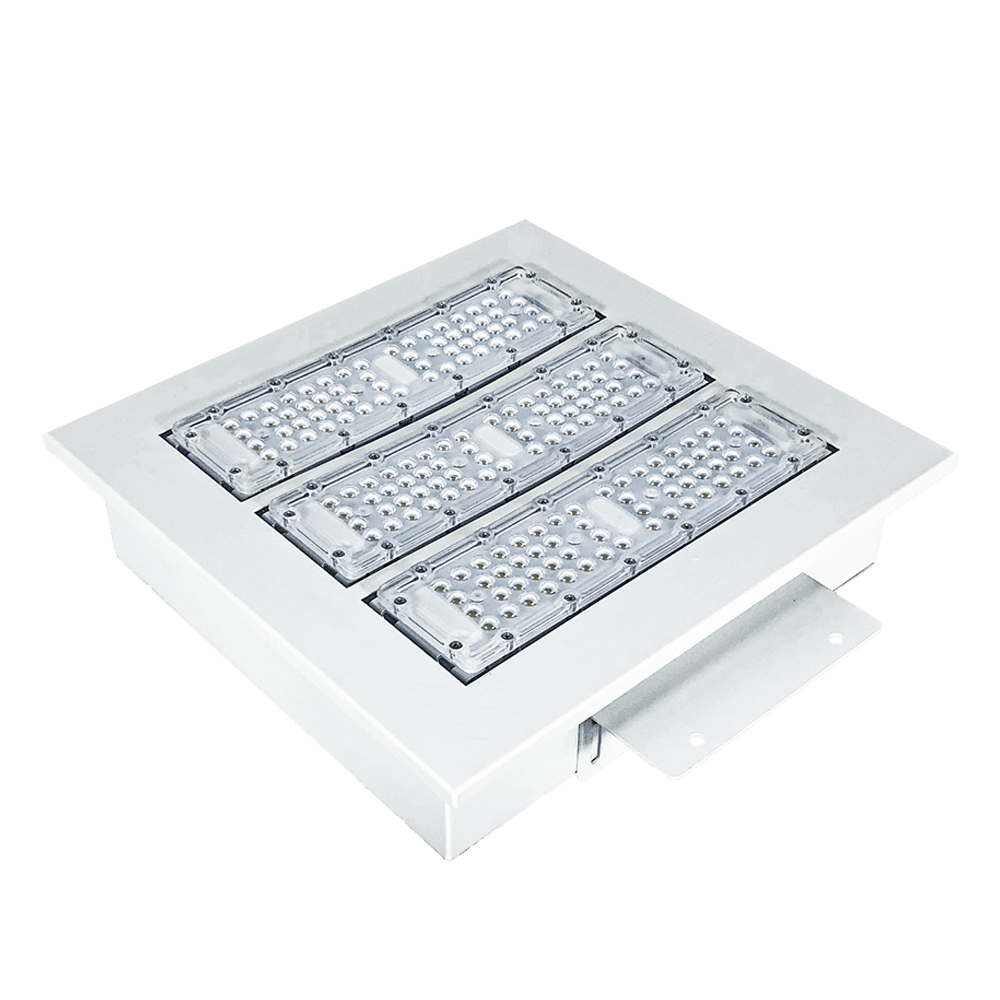

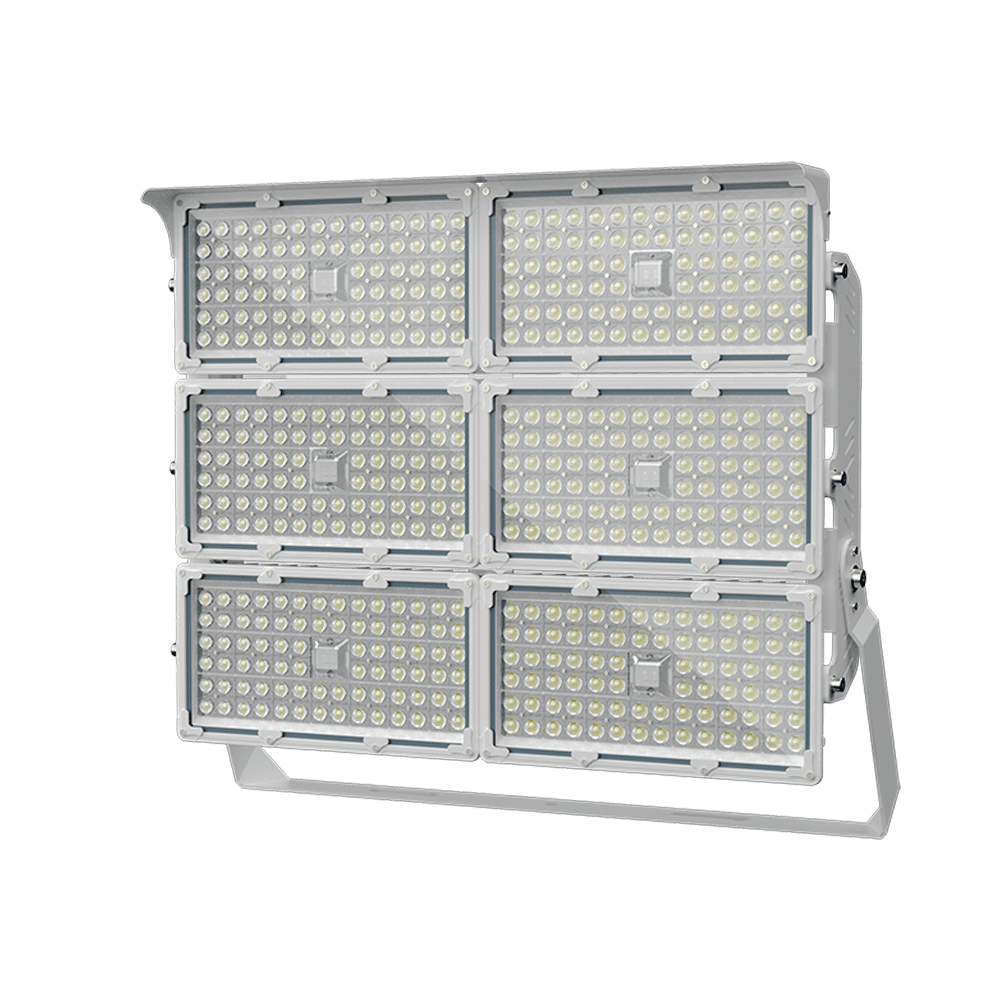

In mining operations, industrial lights are indispensable lighting tools. Due to the complex environment inside mines, UFO high bay lights, with their 360-degree illumination, effectively reduce blind spots and enhance operational safety.

2.Industrial Manufacturing

In factory workshops,Led linear high bay lights are widely used in production lines and assembly areas due to their uniform light distribution and energy-saving features. Good lighting can improve employee efficiency and product quality.

3.Warehouse Logistics

In large warehouses and logistics centers, proper lighting layout can enhance the efficiency of goods picking. The high brightness of UFO high bay lights ensures that goods can be clearly identified at any time.

Considerations When Selecting Industrial and Mining Lights

1.Brightness and Power

Different application scenarios require different brightness levels. When selecting Led industrial high bay lights, determine the required power and brightness based on the specific area size and height. Generally, higher ceilings require brighter fixtures.

2.Protection Rating

Industrial lights typically need to have a high protection rating to withstand dust, moisture, and chemical exposure. Choosing lights with an IP65 rating or higher can effectively extend their lifespan.

3.Energy Efficiency

With increasing environmental awareness, energy-efficient industrial lights are gaining attention. LED industrial high bay lights not only consume less energy but also have a long lifespan, making them suitable for long-term use in industrial environments.

4.Installation and Maintenance

When installing LED industrial lights, consider the height and angle of the fixtures to ensure even light coverage across the workspace. Additionally, pay attention to the ease of maintenance for regular inspections and replacements.

Installation Recommendations for Industrial Lights

1.Proper Layout

When installing industrial Led high bay lights, arrange the fixtures’ positions based on the actual structure of the work area. Generally, lights should be evenly distributed to avoid poorly lit areas.

2.Power Supply Selection

Choose appropriate power supply and switch devices to ensure the safe use of lights. It is advisable to use waterproof and dustproof power equipment to meet the special requirements of industrial environments.

3.Regular Inspections

To ensure the normal operation of Led high bay lights, regular inspections and maintenance are recommended. Timely replacement of damaged fixtures is essential to maintain lighting effectiveness.

The importance of Led industrial high bay lights in industry and mining cannot be overstated. Through proper selection and installation, the safety and efficiency of the work environment can be greatly enhanced. Whether choosing UFO or linear industrial lights, suitable selection and scientific installation are key to ensuring optimal performance. We hope this article provides valuable insights for your application and selection of Led industrial high bay lights.